- Home

- About Us

- Products

- Projects

- Gallery

- Contact Us

Apex Brickcutters has been in operation as a brick merchants, brickcutters providing

cast stone, brick arches and other types of special shaped bricks for over 20 years.

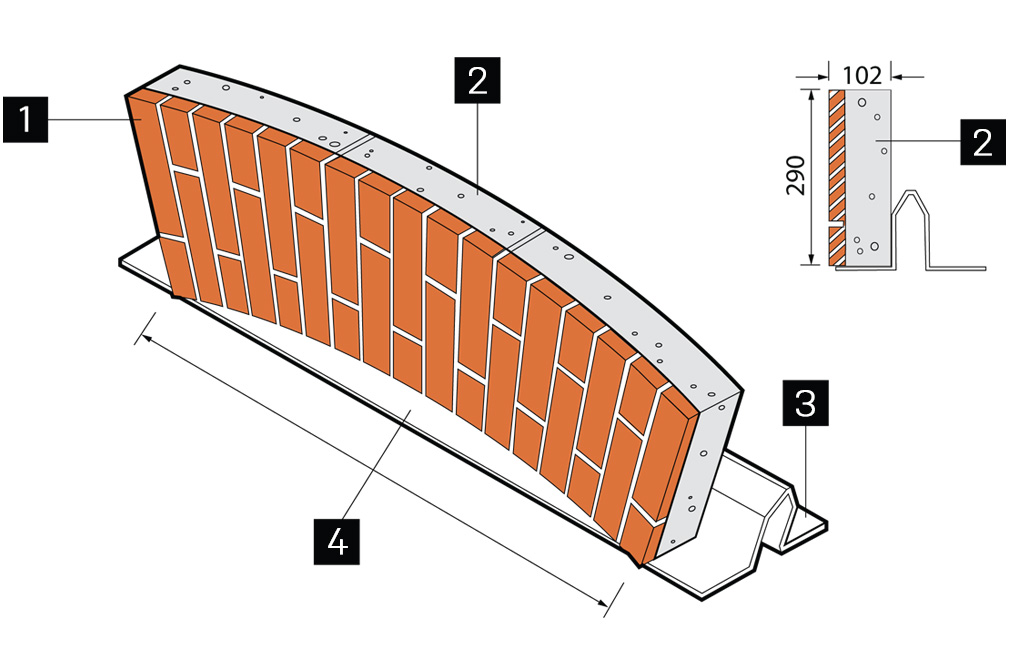

Apex Brickcutters manufacture Preformed Arches, bonding brick slips to a lightweight backing.

Apex ‘Eazy’ Brick Arches are lightweight but with a crushing strength of 13N. They are available in any size and style and in 7-10 working days from order. These Brick Arches are made from 30mm Brick Slips bonded to 70mm Structural Insulated Panel (SIP) Board. All our preformed arches are made with BBA approved SIP Board and Epoxy Resin – Read about our BBA Accreditation here.

This method of Brick Arch is to be used in conjunction with a steel supporting lintel and is commonly used by the major Housebuilders.

These arches are designed to replicate the appearance of traditional brick arches but are much lighter and easier to install, making them ideal for non-load-bearing applications or where a full brick arch isn't feasible. Made from brick slips adhered to a lightweight backing, such as steel or fibre-reinforced concrete.

The use of thin brick slips reduces the weight significantly compared to full brick arches, making them easier to transport and handle on-site. Due to their lightweight nature they are generally a 1 man lift, complying with health and safety regulations regarding heavy lifting. Manufactured off-site, these arches arrive ready to install, reducing on-site labour and ensuring consistent quality and precision. These arches are often used in both new builds and renovations

These arches are typically non-load-bearing and rely on additional support for strength, such as being used in conjunction with a steel supporting lintel.

Lead Time 7-10 Days.