- Home

- About Us

- Products

- Projects

- Gallery

- Contact Us

Apex Brickcutters has been in operation as a brick merchants, brickcutters providing

cast stone, brick arches and other types of special shaped bricks for over 20 years.

Apex Brickcutters manufacture loose cut arches from real bricks.

These are produced by cutting standard bricks, using diamond tipped masonry saws with fresh water coolant, this ensures that the finished product has the sharp, accurate arrises that you would expect from traditional cut brick arches. Each arch is delivered to site on a board that is shrinkwrapped and clearly labelled.

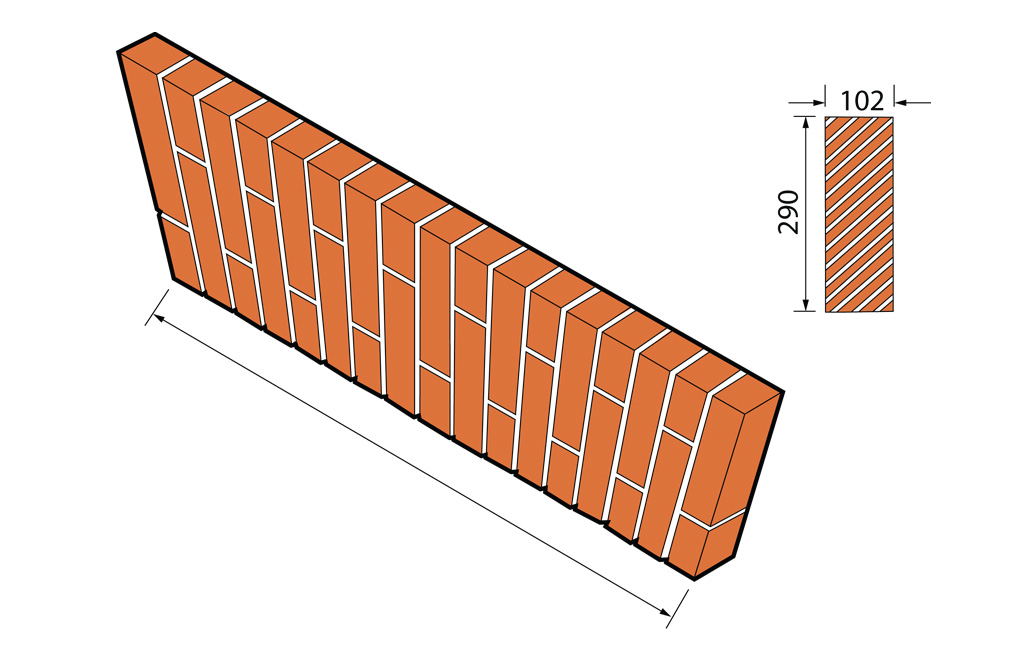

Illustration shows an example Solid Brick Loose Cut Arch using bricks from site.

Each brick is shaped and sized to fit the arch shape. Temporary support holds the bricks until the arch stands alone. Skilled masons build loose cut brick arches, ensuring proper placement for structural soundness. Loose cut arches offer customisation for various sizes, shapes, and architectural styles.

Loose cut brick arches offer a timeless aesthetic that complements a wide range of architectural styles. They can be customised to incorporate complex curves and decorative elements, providing a unique and personalised look. Loose cut brick arches are known for their exceptional durability and structural integrity.

Building a loose cut brick arch requires skilled labor and can be time-consuming and labor-intensive. The need for formwork can add to the cost and complexity of the project.

Lead Time 5-7 Days.

For a quicker and simpler solution see our Preformed (Lightweight) arches.