- Home

- About Us

- Products

- Projects

- Gallery

- Contact Us

Apex Brickcutters has been in operation as a brick merchants, brickcutters providing

cast stone, brick arches and other types of special shaped bricks for over 20 years.

Apex Brickcutters have 3 methods of manufacturing pre-formed structural brick arches:

1. Concrete Backed – These arches are cut into 25mm brick slips which are bonded with BBA Approved Epoxy Adhesive to a Load bearing concrete lintel. This is the least expensive method and saves considerable time when installing into a building. The arches have steel or concrete barers that sit on the abutment brickwork for added structural support.

Lead Time – 5-6 Weeks.

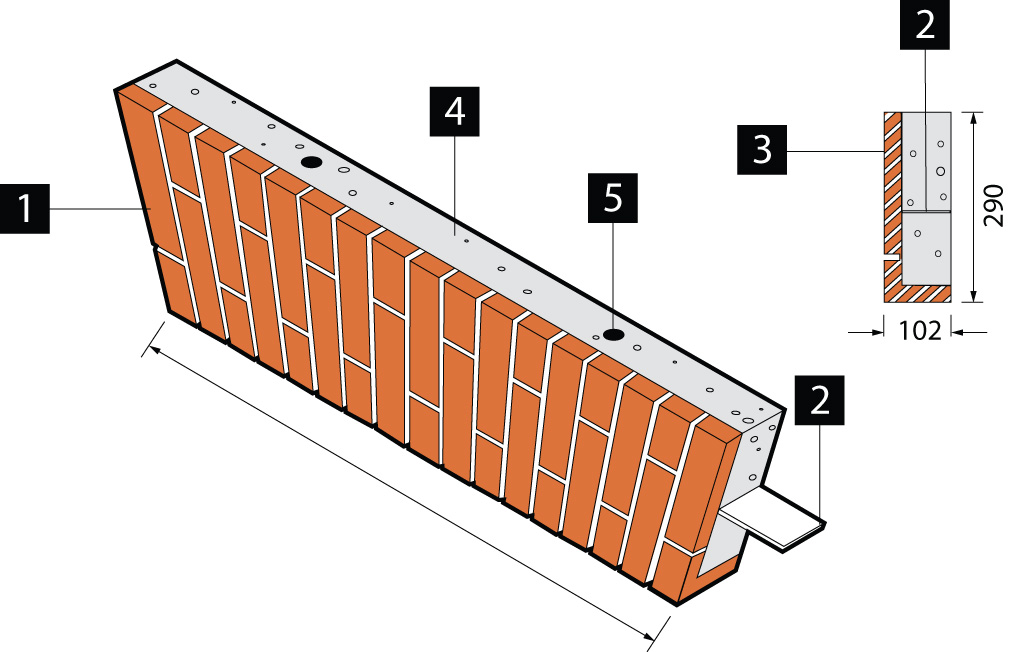

2. Pre-cast Concrete Backed – These arches are cut into 35mm slips with 10mm dovetails cut into the reverse of the slip to provide a key for when the arches are set into the concrete backing lintels. This method is predominantly used for when bricks are in an underslung position of a building. Used for: Walkthroughs, Drive- Thru, Tunnels and Brick Panels.

Lead time – Dependant on complexity of design.

3. Steel Backed – As type 1 but bonded to steel backing lintels. Using Steel lintels means the arch can come fixed to a cavity lintel straddling both skins of brickwork and blockwork.

Lead Time – 2/3 weeks.

A pre-formed structural brick arch is a ready-made unit designed for quick installation, with brick slips set into a rigid framework for support. These arches replicate traditional designs, offering the same load-bearing capabilities and aesthetic, but with faster installation and reduced on-site labour.

These offer faster installation and easier handling due to its lightweight design. It replicates the look of traditional brick arches while using brick slips, reducing the load on the structure. The precision of off-site manufacturing ensures consistent quality, and its lighter weight makes it ideal for projects where full bricks aren't feasible, while still achieving the same aesthetic and structural efficiency.

This is the most expensive method of arch construction, with the longest lead time.

Lead Time 3/4 Weeks.

For a more traditional solution using full bricks, see our Loose Cut arches.