- Home

- About Us

- Products

- Projects

- Gallery

- Contact Us

Apex Brickcutters has been in operation as a brick merchants, brickcutters providing

cast stone, brick arches and other types of special shaped bricks for over 20 years.

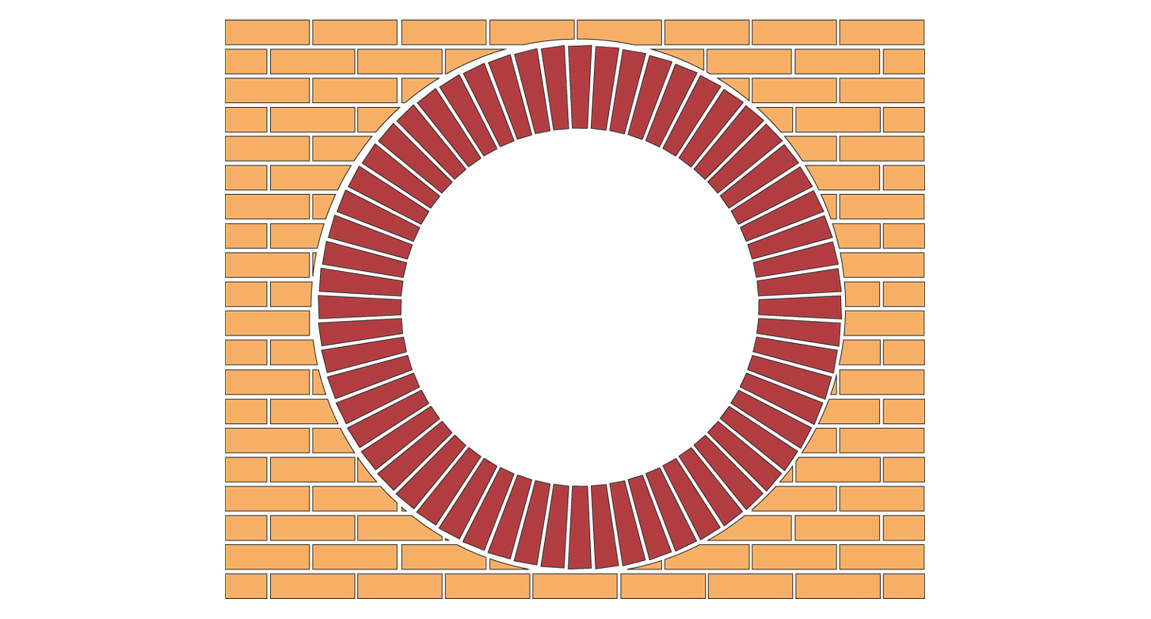

Apex Brickcutters Ltd has 3 methods of manufacturing brick arches as follows:

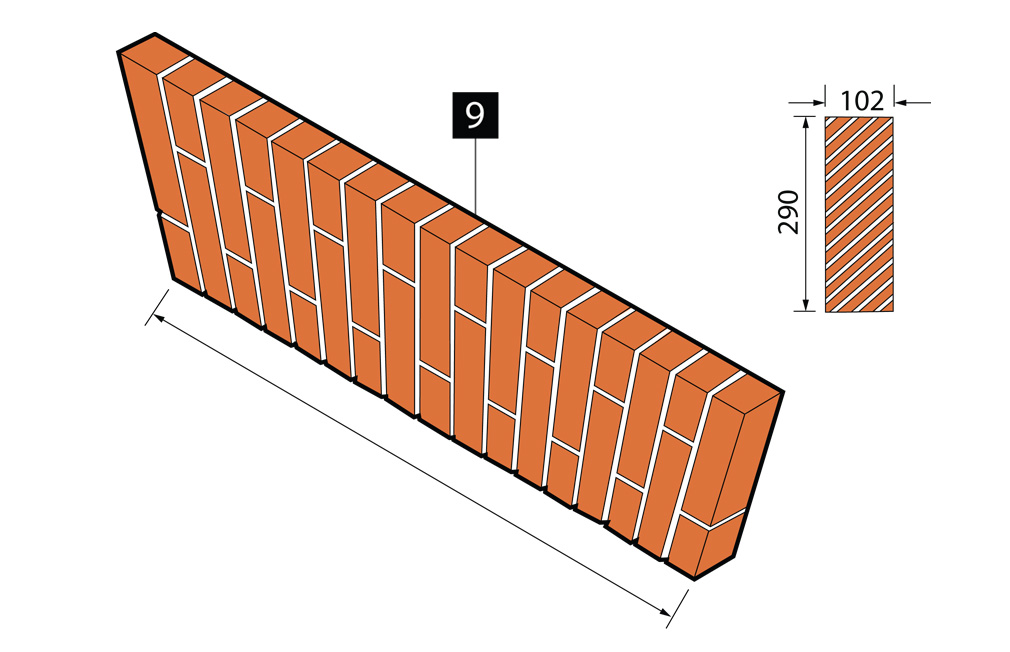

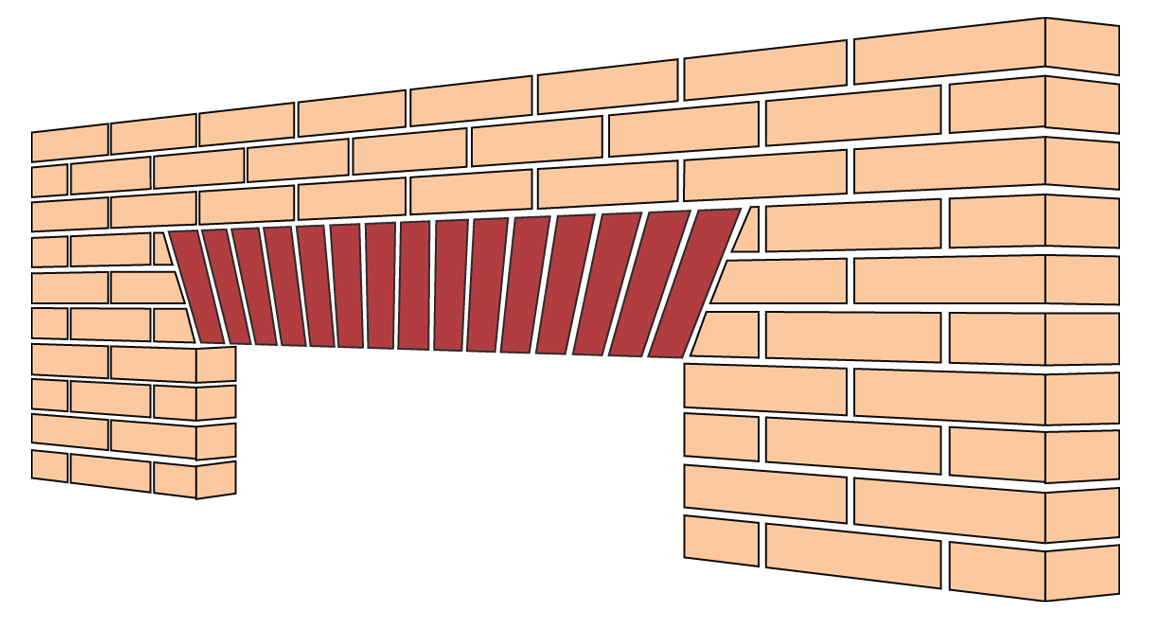

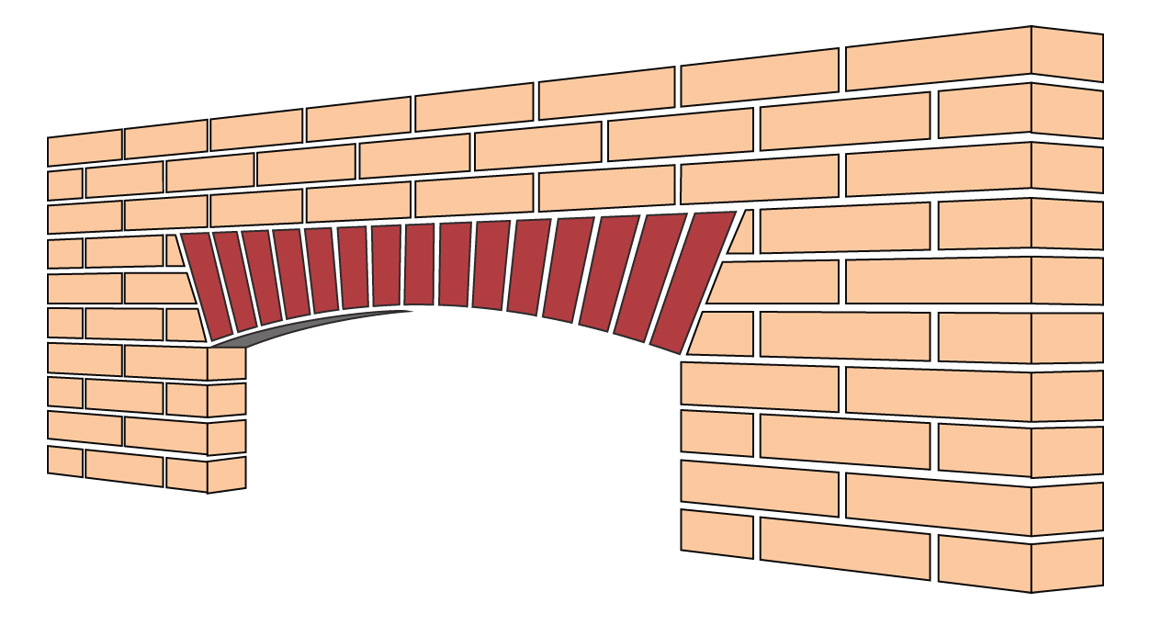

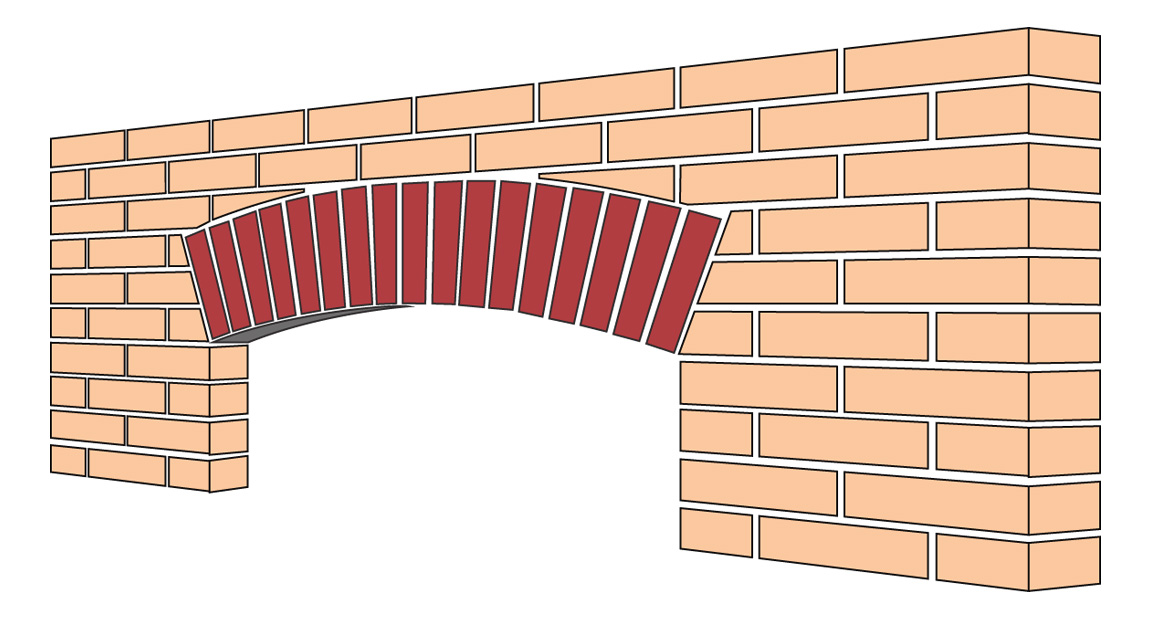

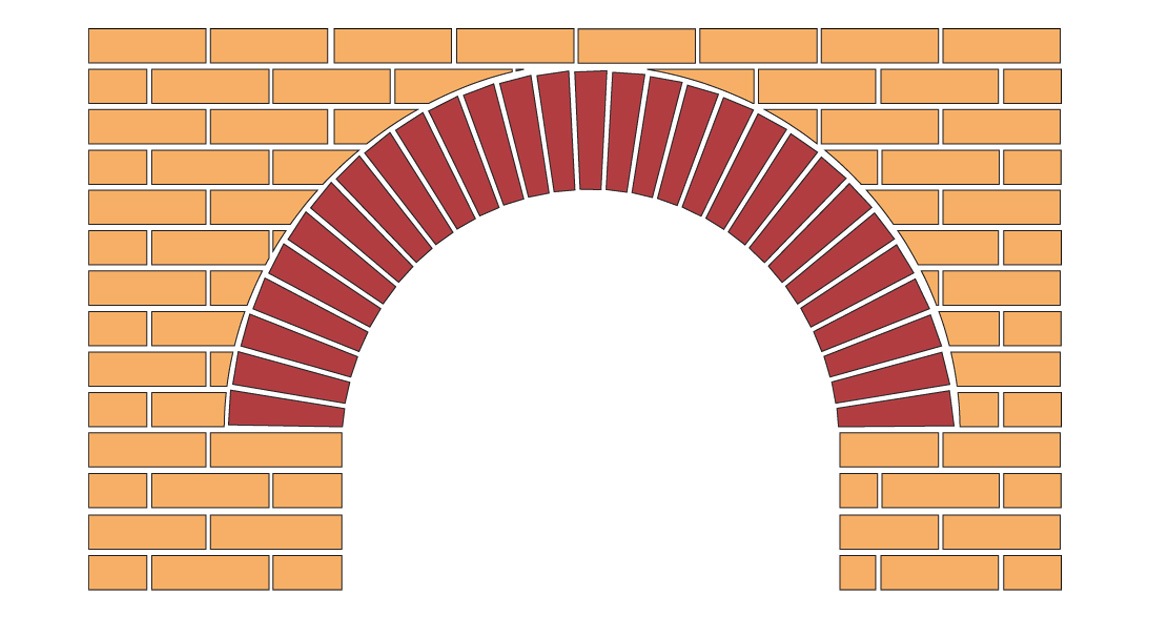

1. Loose Cut – These arches are cut into individual voussoirs (Arch bricks). The arch is shrinkwrapped to a board ready for site installation by the bricklayer. The arch is designed to support its own weight therefore a catnic lintel is required above the opening to support the arch and the weight above. This is the cheapest method but takes the longest amount of time to install.

Lead Time 7-10 Days – Find out more about our Loose Cut Arches.

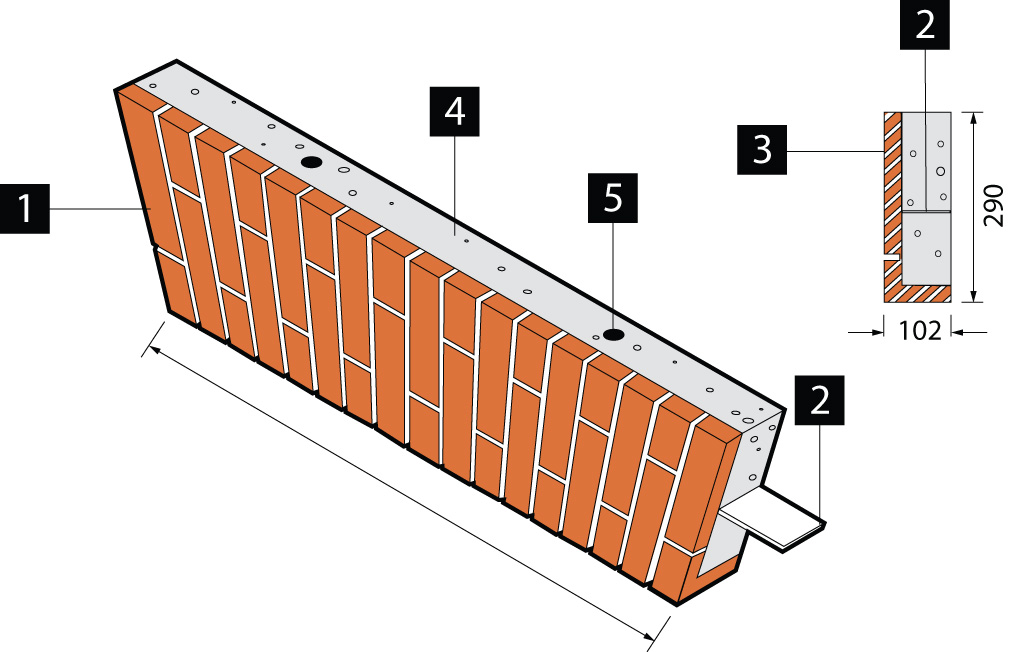

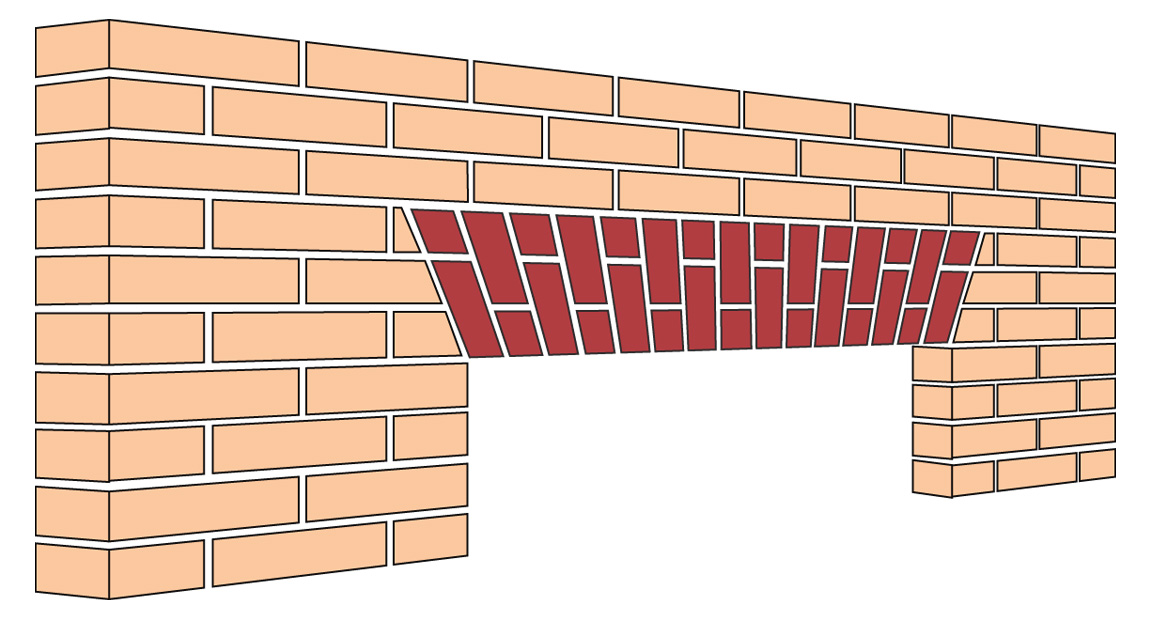

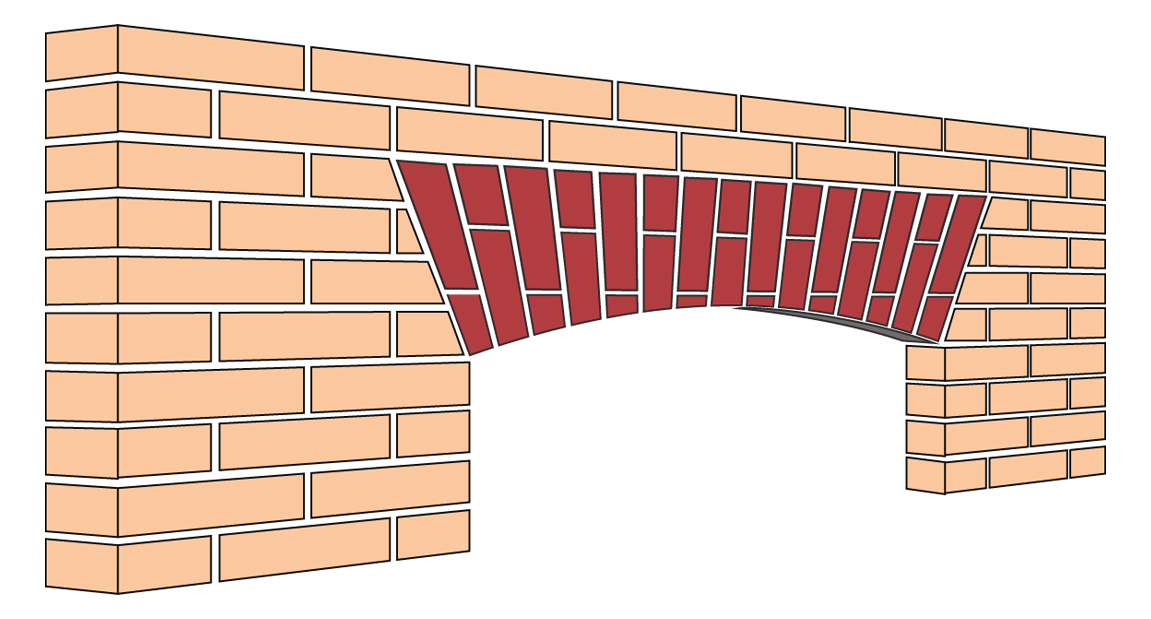

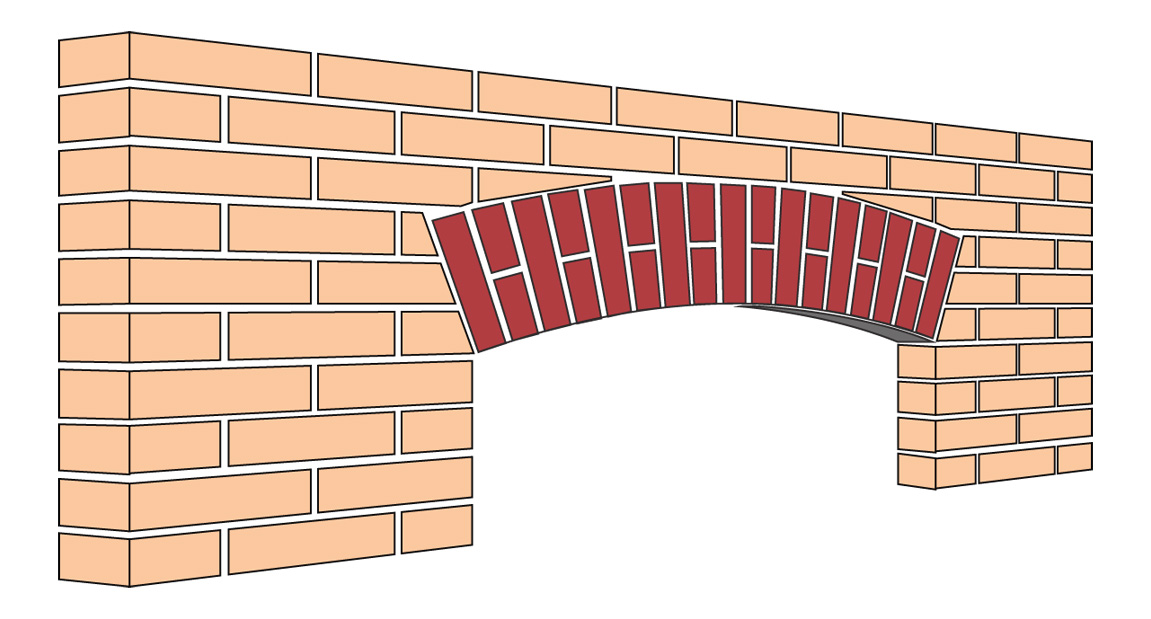

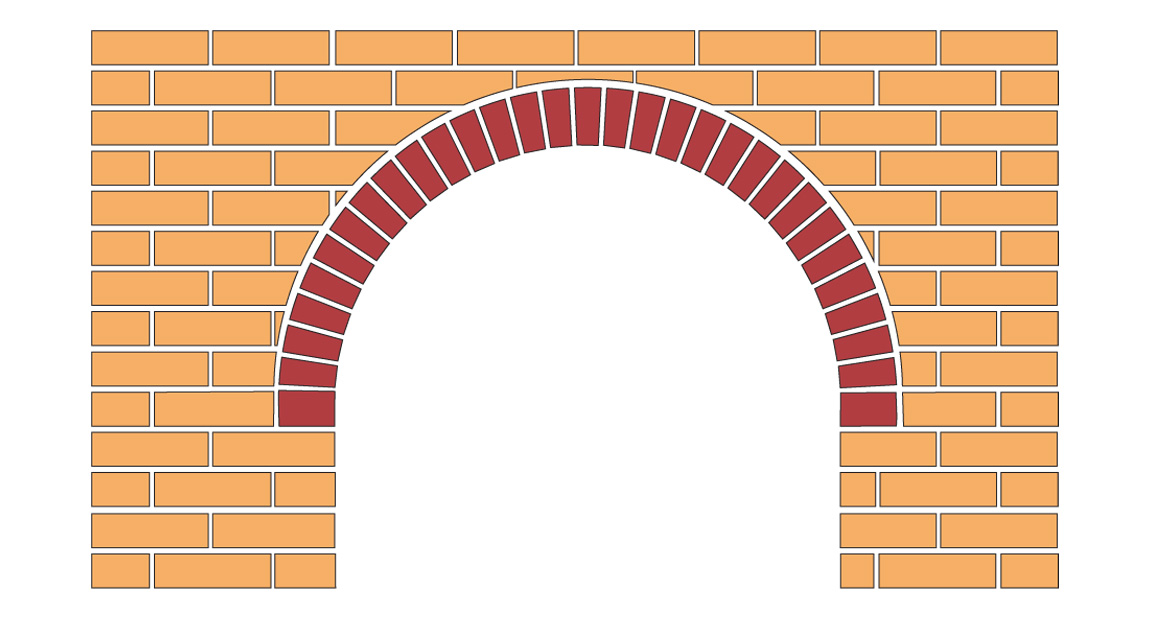

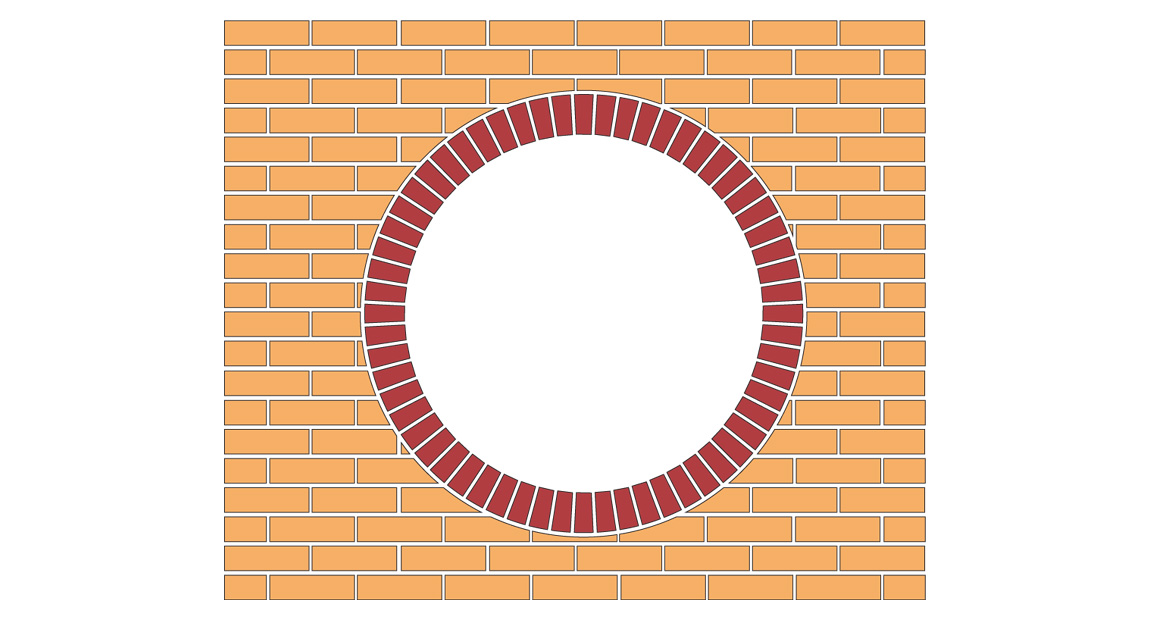

2. Preformed (Lightweight) – These arches are cut into 22mm brick slips and then bonded to a 80mm lightweight backing block, to achieve 102.5mm soffit. The arch is again designed to support its own weight therefore a catnic lintel is required beneath the arch to carry the weight above. This method is more expensive than loose cut but reduces considerably the time taken to install.

Lead Time 10-14 Days – Find out more about our Preformed Arches.

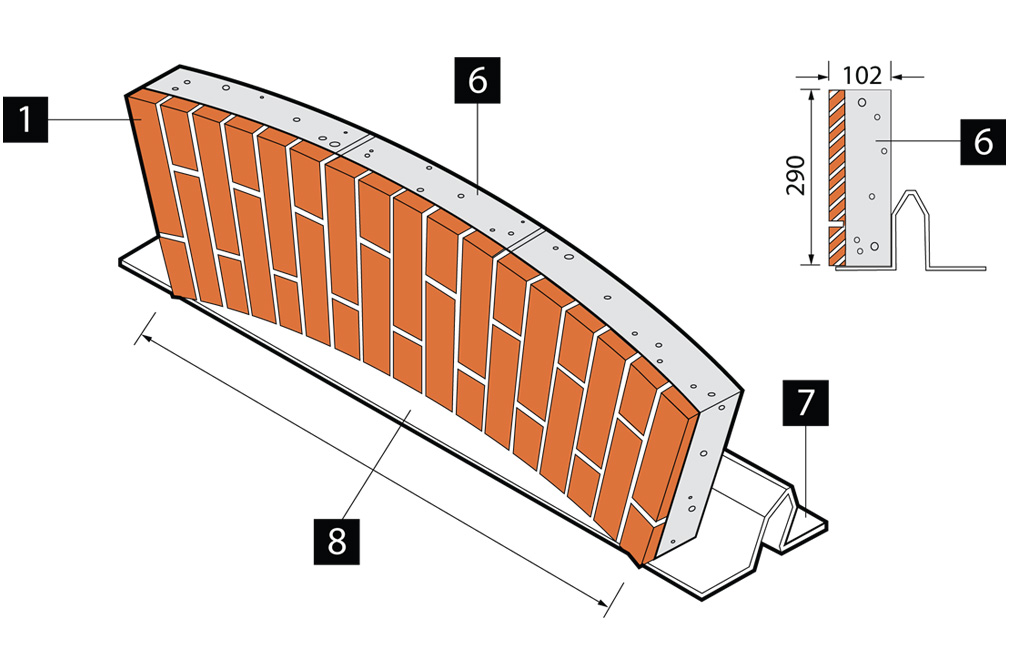

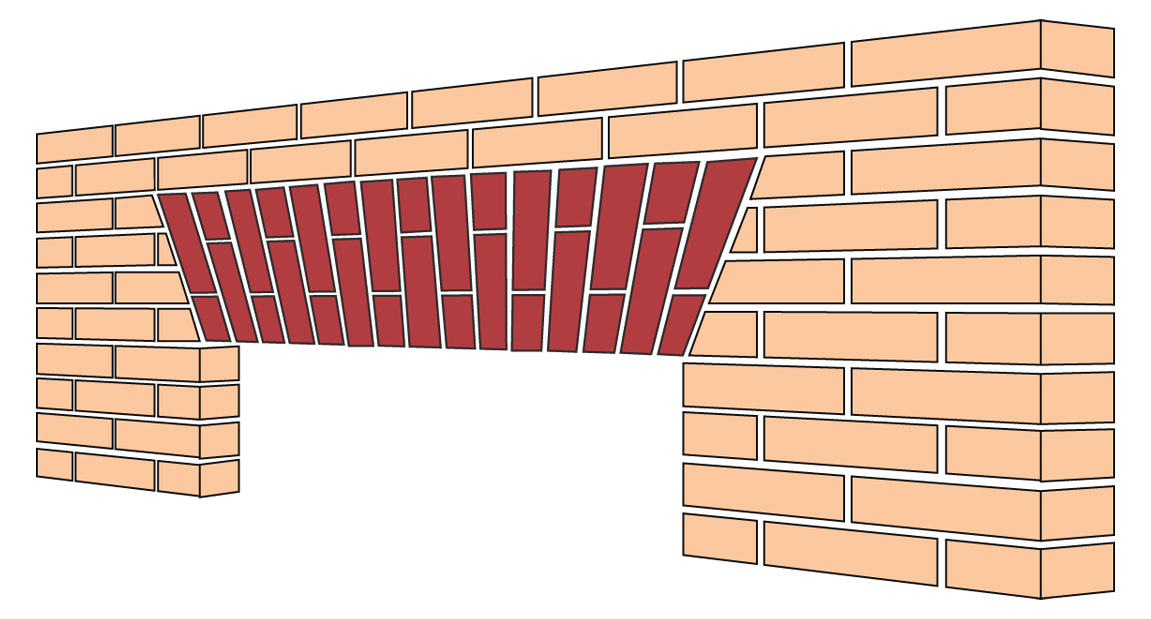

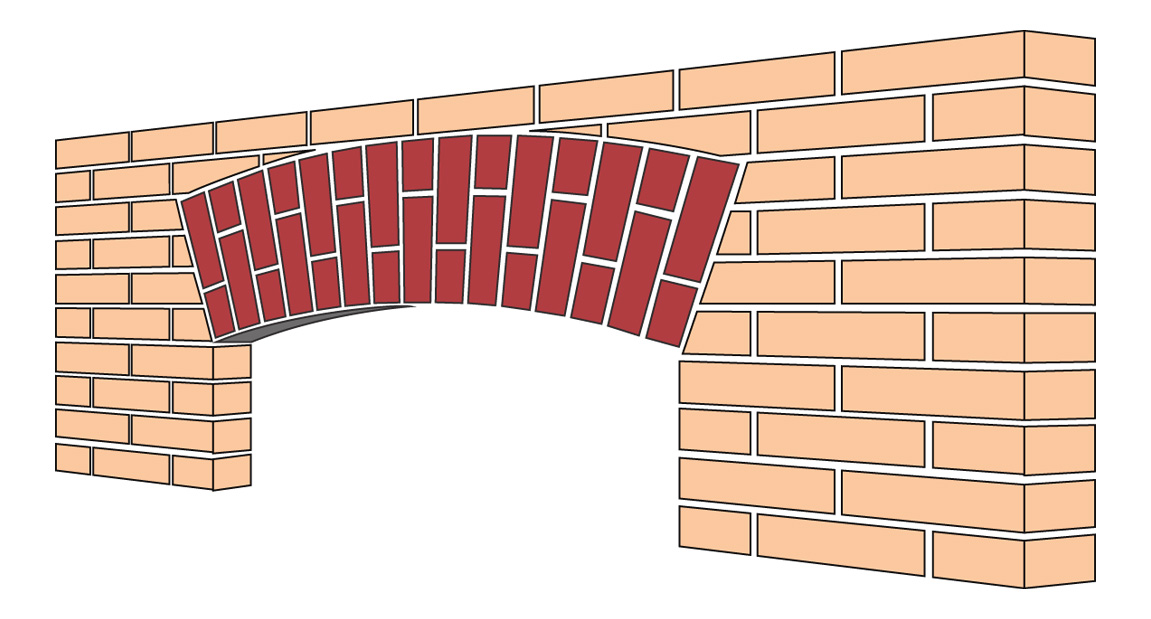

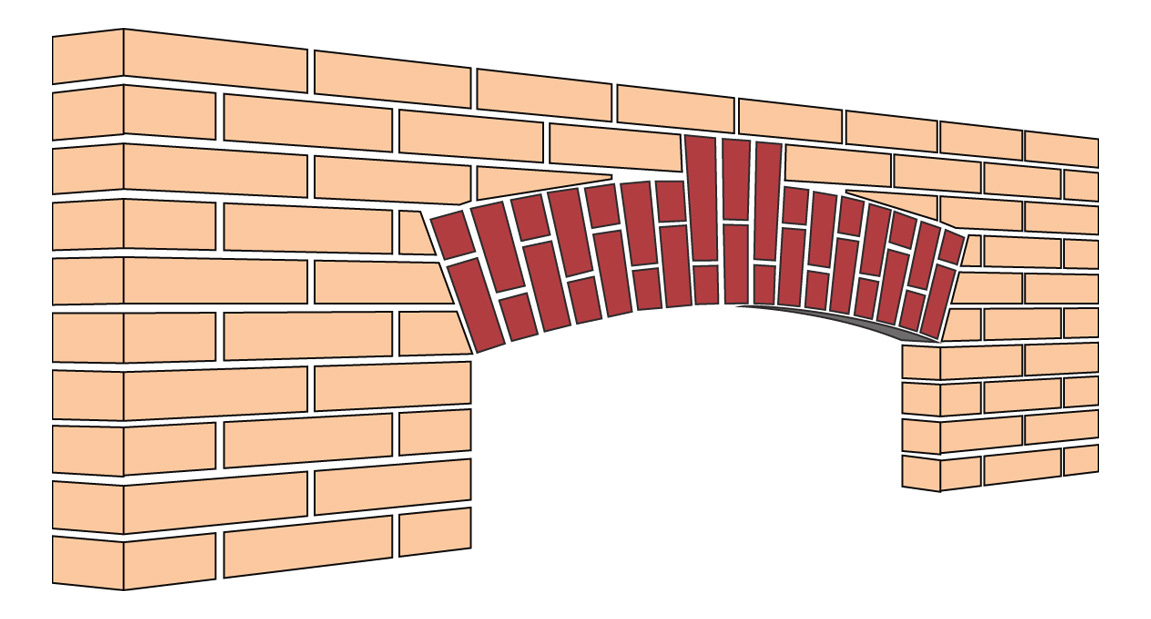

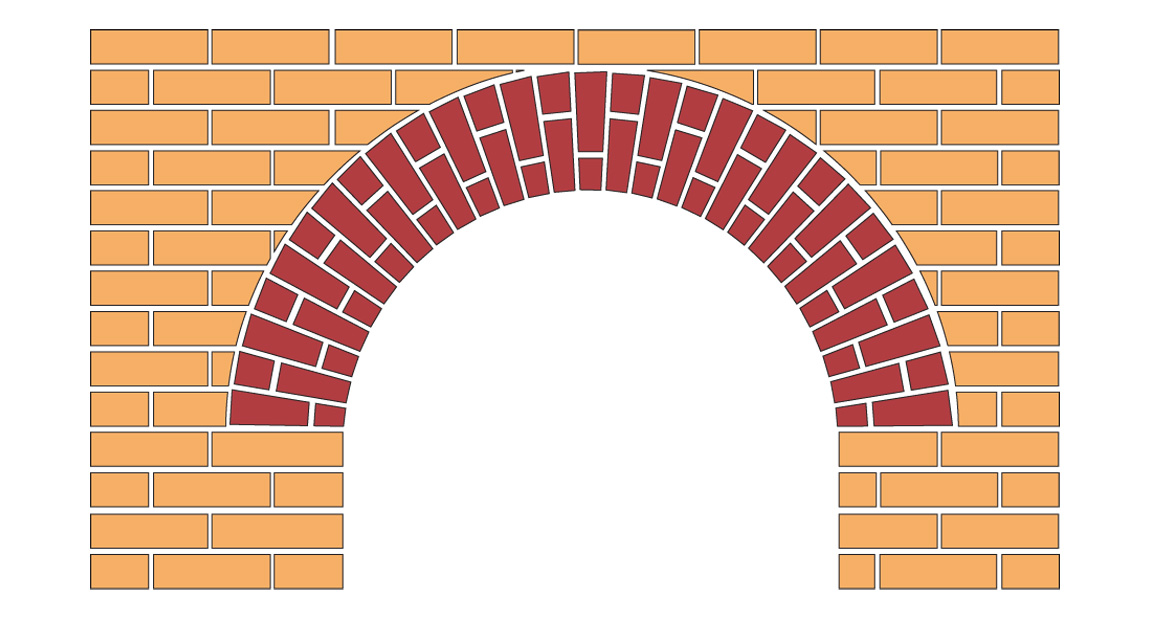

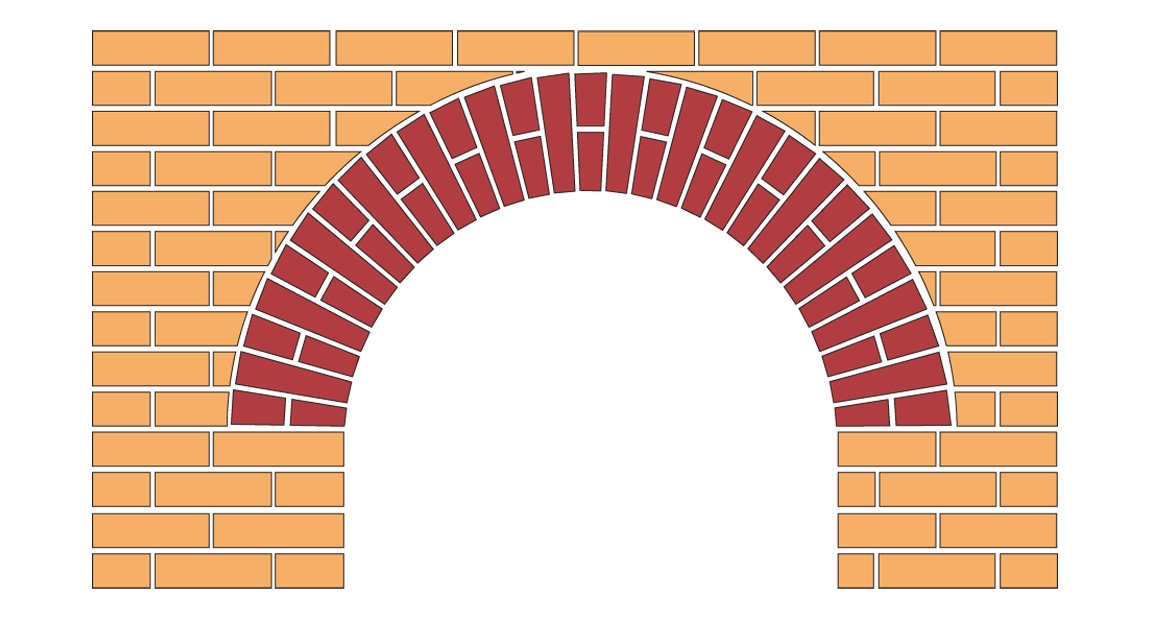

3. Structural – These arches are cut into 25mm brick slips which are bonded to a Load bearing concrete or steel lintel. As they are load bearing the customer has no requirement for an external skin lintel as they can continue to build on top of the arch.This method also allows for the arch to be seen from beneath with a 102mm Brick Faced Soffit if your window is set back from the brickwork. This is the most expensive method but again saves considerable time when installing into a building.

Lead Time 4-6 Weeks – Find out more about our Structural Arches.

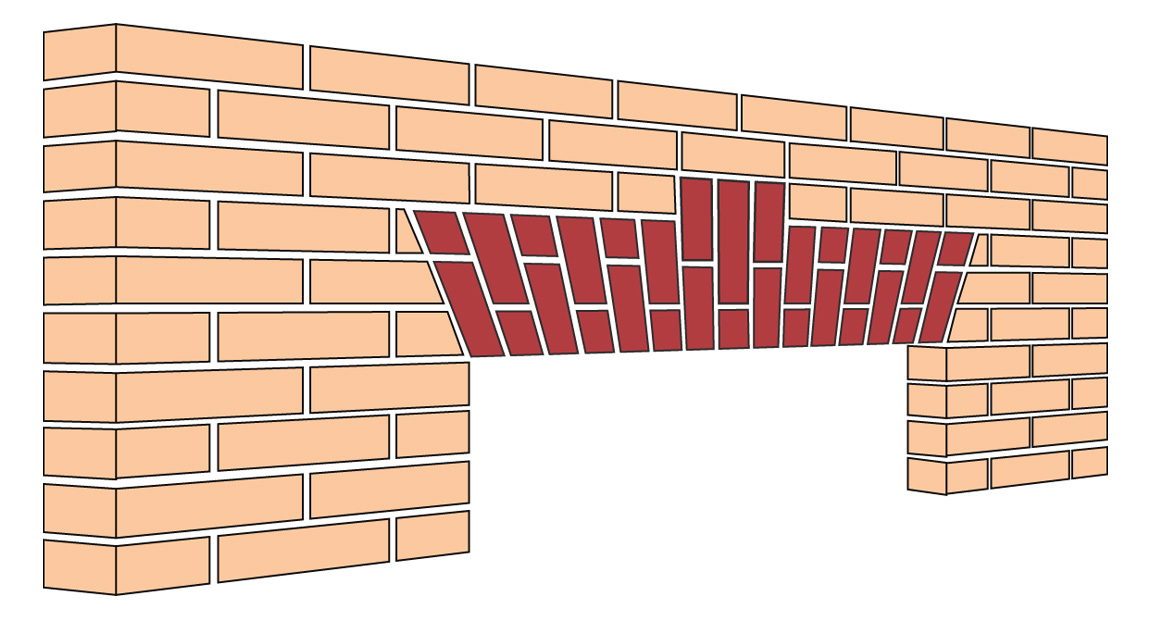

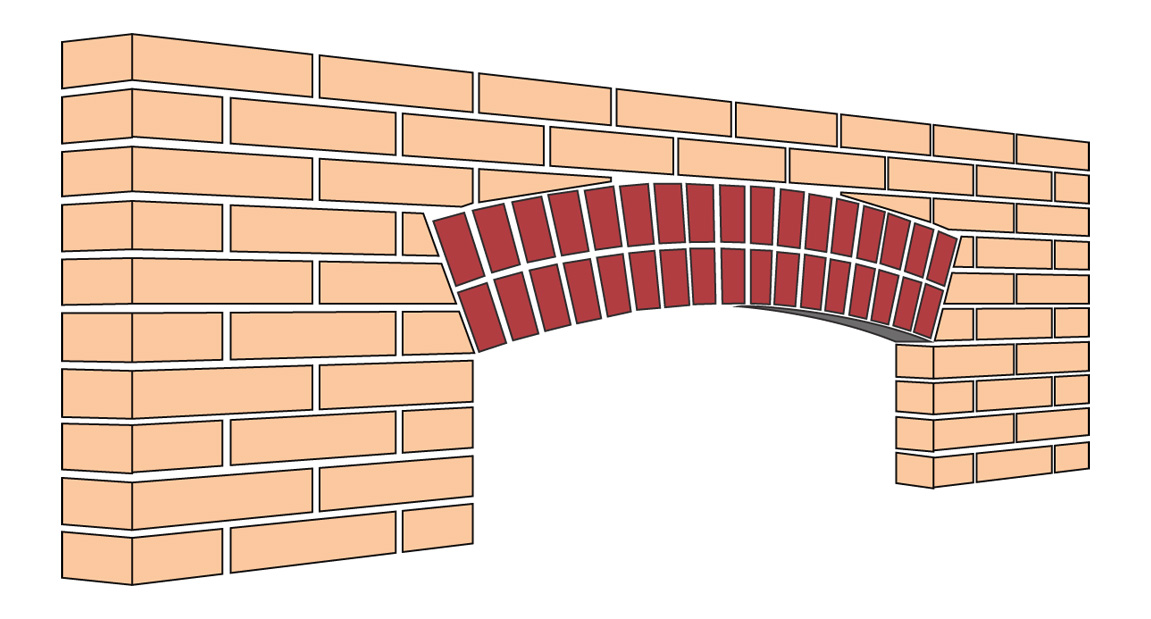

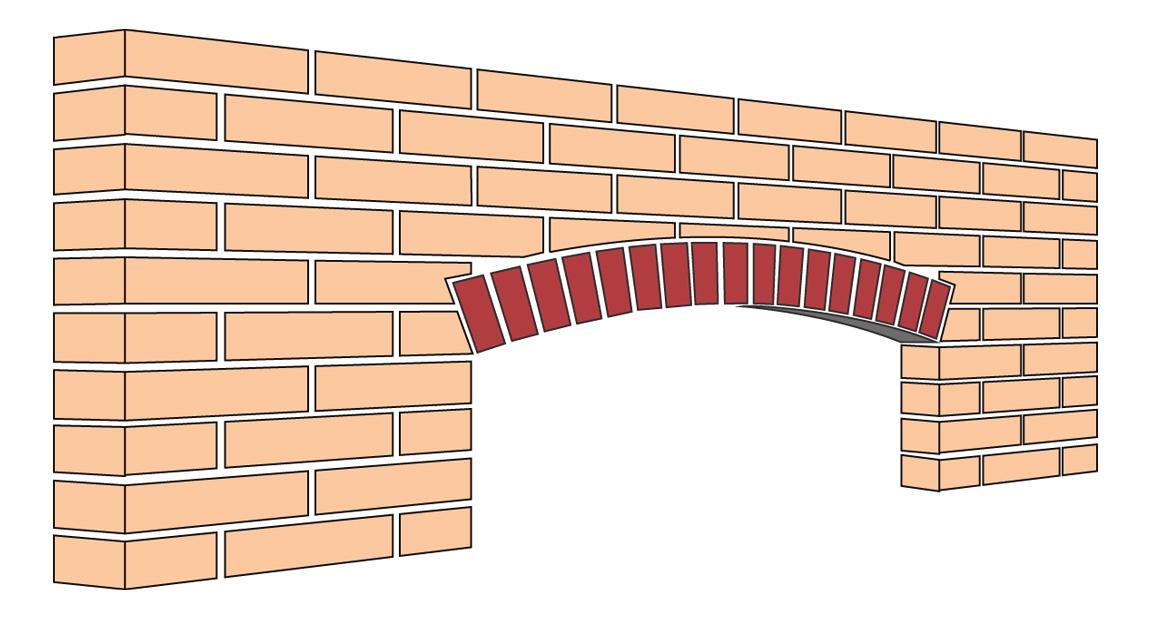

Pre-formed and Structural methods need to be pre-pointed, by site, before installation, to ensure the concrete mix is consistent throughout the development. Alternatively, give your arches a traditional look and ask us to pre-point them with lime effect 4mm Joints. We also supply red rubber bricks ideal for refurbishment and conservation projects.

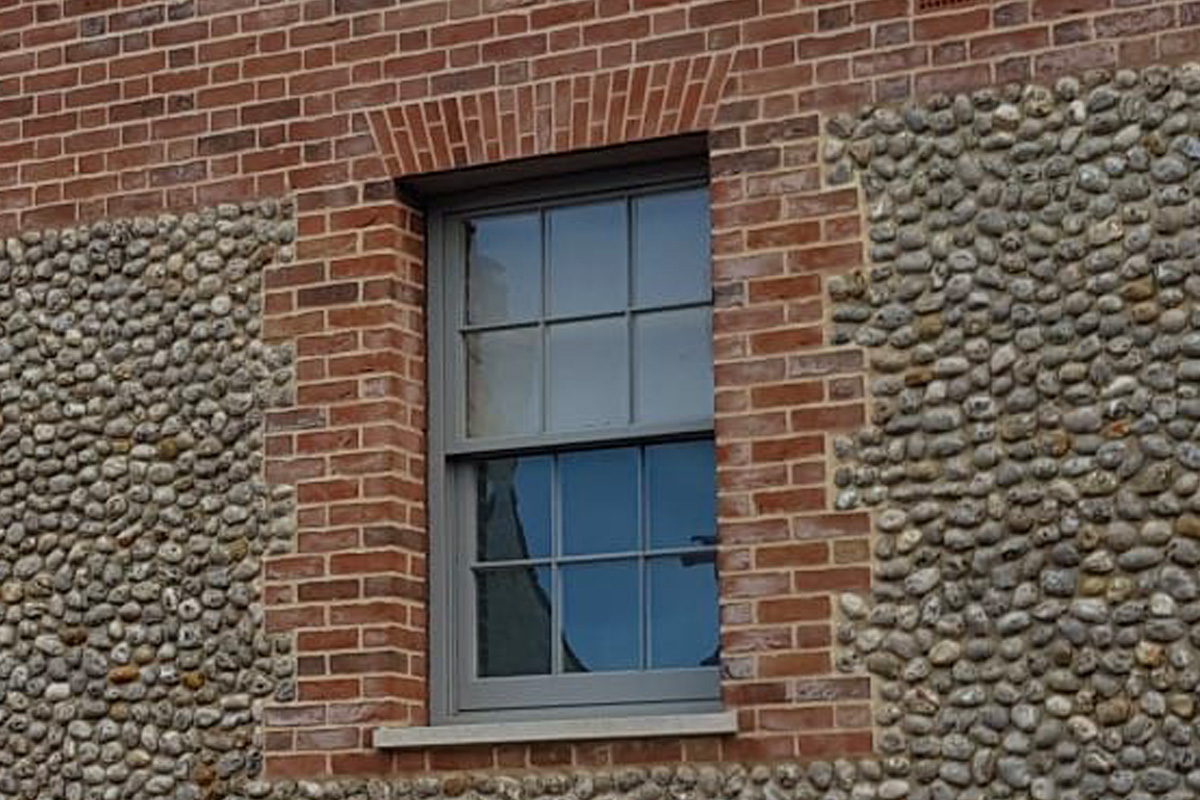

A lot of our work is involved in matching arches in old buildings where extensions are being built or restoration work is being undertaken. If you have a project of this nature one of our technical sales team will visit the site and ascertain all the information necessary to produce arches as close to the originals. Drawings can be produced if required. we have stock of imperial sized clay rubbing blocks.